Saftherm is a modern high-tech enterprise integrating R&D, production, sales, and technical services.SAFTHERM brand and product series are highly praised by customers at home and abroad.

We provide 1200°C, 1400°C, 1700°C, 1800°C Muffle furnace, Vacuum furnace, Tube furnace, Vacuum atmosphere furnace, Bogie Hearth Furnace, Industrial furnace, Large lifting furnace, Sintering furnace and other heating equipment and technical solutions.

SAFTHERM products had been delivered to more than 82 countries including Europe, North America, South America, Asia, Africa, Oceania etc .SAFTHERM provide laboratory heating equipment and heat treatment high temperature equipment and technical services for universities, scientific research institutes, factories and enterprises, petrochemical, petroleum, smelting, casting, machinery manufacturing, military industry and many other industries.

Industrial our solutions for your application

Laboratory / University

+

Aerospace

+

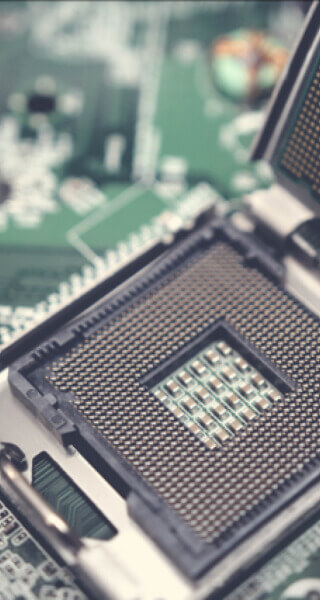

Electronics

+

Chemistry / Plastics

+

Ceramics / Glass

+

Materials Research

+

From September 28th to September 30th, 2025, all members of Henan Sante Furnace Industry will conduct a three-day and two night team building activity in Xinyang City. The purpose of this trip is to enrich the cultural life of employees, enhance team cohesion, and allow everyone to relax and share beautiful moments in their busy work schedules.

Customised industrial furnaces for Belgian customers

Submit Request