9.15 The partners of Santoku Furnace Technology Co., Ltd. embarked on a group tour of Yuntai Mountain, the staff on the road were laughing and full of expectations. Enjoy the happiness in the activity, and get the growth in the happiness!

9.15 The partners of Santoku Furnace Technology Co., Ltd. embarked on a group tour of Yuntai Mountain, the staff on the road were laughing and full of expectations. Enjoy the happiness in the activity, and get the growth in the happiness!

9.15 The partners of Santoku Furnace Technology Co., Ltd. embarked on a group tour of Yuntai Mountain, the staff on the road were laughing and full of expectations. Enjoy the happiness in the activity, and get the growth in the happiness!

9.15 The partners of Santoku Furnace Technology Co., Ltd. embarked on a group tour of Yuntai Mountain, the staff on the road were laughing and full of expectations. Enjoy the happiness in the activity, and get the growth in the happiness!

9.15 The partners of Santoku Furnace Technology Co., Ltd. embarked on a group tour of Yuntai Mountain, the staff on the road were laughing and full of expectations. Enjoy the happiness in the activity, and get the growth in the happiness!

9.15 The partners of Santoku Furnace Technology Co., Ltd. embarked on a group tour of Yuntai Mountain, the staff on the road were laughing and full of expectations. Enjoy the happiness in the activity, and get the growth in the happiness!

Advantages of tilting rotary tube furnace:

1. The furnace tube motor can rotate 360 degrees, suitable for uniform sintering of mixed materials.

2. The furnace is made of various materials, such as alumina ceramic fiber board, stainless steel, quartz, etc., suitable for various material scenarios.

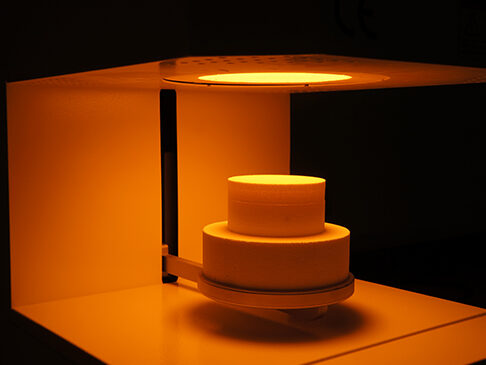

Dental Sintering furnaces play a crucial role in the sintering process of dental restorations, particularly those made from zirconia. This process transforms the milled zirconia framework into a strong, biocompatible final product. Dental sintering furnaces are used to process dental zirconia after it has been milled into a crown , bride , framework or other restoration

How to Choose Vertical Tube Furnaces?Different types of tube furnaces have their own advantages. Choosing a right tube furnace is important to your heat treatments performance.

Submit Request