Saftherm is a modern high-tech enterprise integrating R&D, production, sales, and technical services.SAFTHERM brand and product series are highly praised by customers at home and abroad.

We provide 1200°C, 1400°C, 1700°C, 1800°C Muffle furnace, Vacuum furnace, Tube furnace, Vacuum atmosphere furnace, Bogie Hearth Furnace, Industrial furnace, Large lifting furnace, Sintering furnace and other heating equipment and technical solutions.

SAFTHERM products had been delivered to more than 82 countries including Europe, North America, South America, Asia, Africa, Oceania etc .SAFTHERM provide laboratory heating equipment and heat treatment high temperature equipment and technical services for universities, scientific research institutes, factories and enterprises, petrochemical, petroleum, smelting, casting, machinery manufacturing, military industry and many other industries.

Industrial our solutions for your application

Laboratory / University

+

Aerospace

+

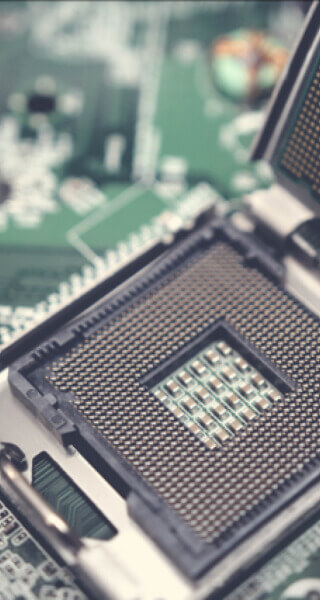

Electronics

+

Chemistry / Plastics

+

Ceramics / Glass

+

Materials Research

+

Advantages of tilting rotary tube furnace:

1. The furnace tube motor can rotate 360 degrees, suitable for uniform sintering of mixed materials.

2. The furnace is made of various materials, such as alumina ceramic fiber board, stainless steel, quartz, etc., suitable for various material scenarios.

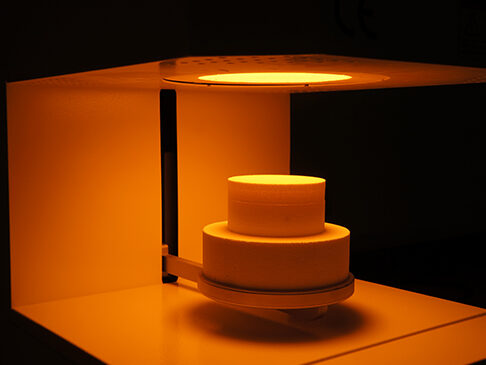

Dental Sintering furnaces play a crucial role in the sintering process of dental restorations, particularly those made from zirconia. This process transforms the milled zirconia framework into a strong, biocompatible final product. Dental sintering furnaces are used to process dental zirconia after it has been milled into a crown , bride , framework or other restoration

How to Choose Vertical Tube Furnaces?Different types of tube furnaces have their own advantages. Choosing a right tube furnace is important to your heat treatments performance.

Submit Request